Design

-

Pro-Built Control was contracted to complete electrification works and control system engineering for a new crushing and screening fixed plant.

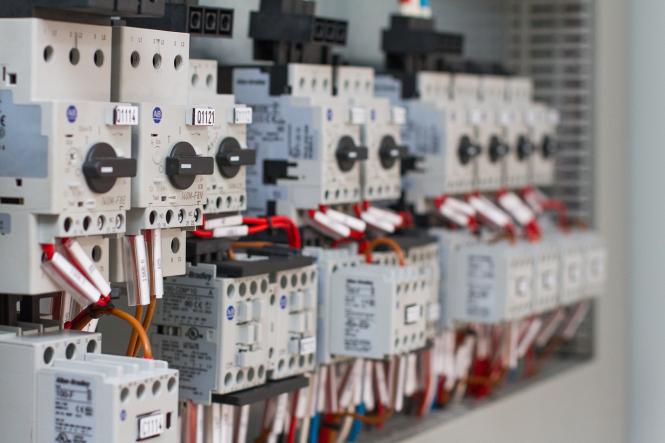

The MCC panels were designed and constructed in our factory using state of the art control hardware from Rockwell Automation. The project utilized a Compact Logix 5380 PLC, E300 DOL starters, SMC Flex Soft Starters, and Powerflex VSD's all communicating on EthernetIP via a Stratix 5700 managed switch.

Pro-Built Control was able to offer a full operator control solution via the PlantPax Libraries with remote access via 4G and local Prosoft wireless network with multiple access points for mobile control of the plant via a tablet.

Onsite field and MCC installation works were completed within 14 days, including cable trays, support systems, and motor cabling.

-

Our customer in the paper industry requested an MCC switchboard upgrade to replace aged existing boards. During the quoting process a fire damaged the existing boards. The project was expedited to provide new CUBIC switchboards to site.

These dual sided switchboards utilize the CUBIC modular system, with ABB ACB's supplying individual feeders containing Allen Bradley E300 electronic overload relays, local operator stations, contactors, and Terasaki circuit breakers.

With the assistance of our suppliers NHP and Remtron, and our electricians split over two shifts per day, and Flexilift forklifts to assist in loading the boards onto the truck, PBC delivered these panels in almost half the original project timeline to get the papermill back up and running.

-

PBC was selected to offer a full turn key electrical solution for a new Primary and Secondary plant.

The mechanical design and equipment selection was through the principle contractor QME P/L located in Bendigo, Victoria.

The scope of works included;- Functional description

- Technical safety specification

- Design of Power distribution and MCC including light and power

- Design of Electrical control system and instrumentation utilizing Rockwell Automation components.

- Complete software and industrial IT design leveraging Allen Bradley PlantPAX libraries, Prosoft 4G remote access, programming and commissioning.

- Manufacture and installation of all electrical systems and field wiring.

- Factory acceptance testing

- On site installation and commissioning.

- Ongoing remote site support.

-

Paper Mill Siemens S5 to DCS Upgrade

Paper Machine S5 upgrade to ABB 800xADCS

The Siemens S5 Processor and IO were converted to Phoenix Contact Axioline Profi-Net IO XC modules communicating with the existing ABB 800xA DCS.All siemens S5 IO relocated to new IO panels, with all outputs individually fused to meet site specifications.

One existing ABB controller (PM861) converted to PM891 to house the new application. Modifications to Profi-Bus & Profi-Net Networks through out the plant were required to accomodate the upgrade and minimise the changeover and commissioning downtime.

In conjunction with the Siemens S5 Upgrade, the ABB DCS System was also upgraded from V4.X to 5.2. This requires a site wide upgrade of new servers and operator stations.

-

Waste Water Permanent Plume Mitigation System Switchboard

Permanent Plume Mitigation System Switchboard

Approx. 400 IO Switchboard and Control Panel containing the following;

- Allen Bradley Compact Logic PLC

- Digital IO, High Speed Counter Inputs, Remote Racks

- ABB Automatic Transfer Switch for 3 phase supply & Generator Backup

- Phoenix Contact Electronic circuit breakers

- UPS

-

Bakery Allen Bradley PLC 5 Upgrade

Non Supported Hardware required upgrading from PLC5 hardware to Allen Bradley Control Logix.

The architecture of the original system was distributed across a local PLC 5 rack containing High speed counter card, analog and digital IO, DH+ Networks for HMI and PLC communications and RIO networks for 11 x field racks. HMI's connected to the system included 2 x PanelView Plus (Ethernet), 1 x PV 550 (DH+). Communications to other PLC's included SLC & Micrologix.

This system was upgraded over 2 weekend shutdowns to reduce impact to production.

The final system comprised of an Allen Bradley L71 processor, high speed counter card, and dual Ethernet cards, with local IO, Flex IO remote racks on Ethernet, and ControlNet with analog and digital IO. HMI's were reprogrammed to access the new L71 processor. The PLC code was translated to Logix 5000. Additional PanelView Plus 600's were installed to replace redundant local displays.

The project was successfully completed with no downtime attributed to the project works.

Duration: 2 months

Staff: 6

I/O count: 1000 -

Our customers brief called for replacement of an ageing MCC and supply cabling used to power 'debarking' machinery in their timber mill.

New electrical control panels required to upgrade the existing MCC were built at Pro-Built Controls premises prior to transporting to site.

The project works included;

- Complete all trenching work to accommodate the new supply including trench depth of 1500mm covered with "Quarter minus" screening compacted and covered with and additional 150mm of reinforced concrete and backfilled with remaining earth.

- Supply and install new 150mm underground conduit (80mtr).

- Supply and install new 100mm conduit for future cabling (40m).

- Supply and install new 185mm 4C & E orange circ cable or equivalent.

- Supply and install new 630 Amp MCCB bucket for the MCC 10.

- Terminate test and energize the new supply.

- Manufacture 4 bay distribution centre to replace the existing MCC & feeds to 16 plant items.

- Remove existing MCC at planned shutdown (2 -3 Days)

- Test and wire new distribution system prior to delivery

- Supply and install 6 fortress key locks to existing guarding in the field.

- Supply and install new fortress master key and key release system.

- Incorporate one lockable 630 amp Circuit Breaker for single point of isolation.

- Test and commission.

- Create CAD electrical schematics and as built drawings

Installation on the eve of Xmas shutdown, commissioning commencing Boxing Day.

-

Control Box & HMI Creation for Conveyor Line.

Project Works include;

- CAT 3 Emergency Stop

- Siemens Touch Panel Programming

- Siemens S7 200 PLC Programming

- Manufacture of Control Panel

Duration: 1 Week

Staff: 2

I/O Count: 30 -

Project requirements - project management, design, install and connect a DCS system to replace dated Siemens S5 and Taylor MOD systems to ABB AC800xA hardware.

The installation was designed in parallel with the existing legacy system enabling full FATs and minimal disruption to production schedules.

All new multicore cables were installed from the final point of field connection to MCC Marshalling panels where the IO was connected to multiple controllers depending on the machine process, prior to change over all new connections were tested from the final point of connection back to the respective controller verifying correct operation of each I/O.

Installation included a new communications network linking all controllers via local Profi-Bus connections through converters to fibre and remote connections, additional server racks were also installed and connected to the DCS network via CAT5 cable.

Testing included analog I/O and application of a process meter to ensure correct scaling.Duration: 12 Months

Change over period: 72 hours

Staff: 20

I/O Count: 8000 -

CO2 Detection & Control System

Project requirements - design, manufacture, program, install & commission a CO2 gas detection, fan & louvre control system for an enclosed winery fermentation area.

Duration: 5 months

Staff: 6

I/O Count: 150 -

Bakery Roll Line Control System Upgrade

This project presented a number of unique challenges for our engineering team including a 48 hour changeover window, missing data & CAD files and insufficient scope documentation. Our engineering staff recreated scope documentation as a forerunner to building, installing and integrating a new control system to suit operational requirements. Integration of the new control system necessitated reverse engineering existing control and equipment function, hardware consisted of approximately 300 I/O utilising an Allen Bradley Compact Logix system coupled with a PV+1500 colour touch screen. System design and layout required conforming to our customers current standards whilst ensuring all applicable industry and regulatory requirements were maintained.

Duration: 12 weeks

Staff: 11

I/O: approx. 300 -

Fire Damaged Electrical Cable Restoration

Fire had caused significant damage to electrical control & power cabling located in underground conduit & ducts.

Pro-Built Control attended an emergency call out to bypass damaged wiring and install temporary power & control. Project restoration works necessitated reverse engineering system operation requirements and associated process control elements.

All field, control and power wiring was traced from point to point to develop working schematics prior to rebuilding/rerouting cable runs.

Duration: 2 days (until startup)

Staff:10

I/O: n/a -

Paper Mill Starch Silos Haz Ex Safety Upgrade

Project requirements - removal, replacement, relocation and modification of plant & equipment located within a 'Hazardous Area' operating environment.

Works included -

- Creation of site area dossier and validation of the customers procured equipment against the site classification documentation, IECex certificates, ANZex/AUSex and current Australian standards for compliance

- Replacement of existing motors, field sensing devices, transmitters, indicators, beacons, 3 Phase outlets, lighting, control panels, field isolator switches, ground monitoring unit, dust collector stop/start control stations with Ex-tD rated components

- Installation/replacement of phase loss protection, Emergency Stop Switches, , intrinsically safe (I.S.) indicator units, new earth bonding conductors

- Replacement of motors with phase loss protection, Field sensing devices, radar transmitters, pressure transmitters, weight indicators, indicating beacons, power outlets, lighting, control panels, field isolator switches, ground monitoring units and push button stations with Ex-tD, Ex-Ia/b, Ex-e, Ex-n rated components

- Testing, dry/wet commissioning and H-class inspections of equipment to comply with current Australian standards including ITP, ITR, commissioning calibration, earth bond resistance and COES documentation.

Duration: 5 months

Staff: 6